SCAN OPTICAL SCANNING

« The Vici Vision range has more than 20 models of machines for the automatic control of cylindrical parts up to a diameter of 180 and a length of 1250 mm.

Vici Vision machines measure the external profile of the part by optical scanning.

Get in a few seconds all the ribs on your parts : lengths, diameters, angles, radius, threads, shape defects, beats, coaxialities …»

teach

automatisation

MK2 fixturing

barcode

static and dynamic

measurement

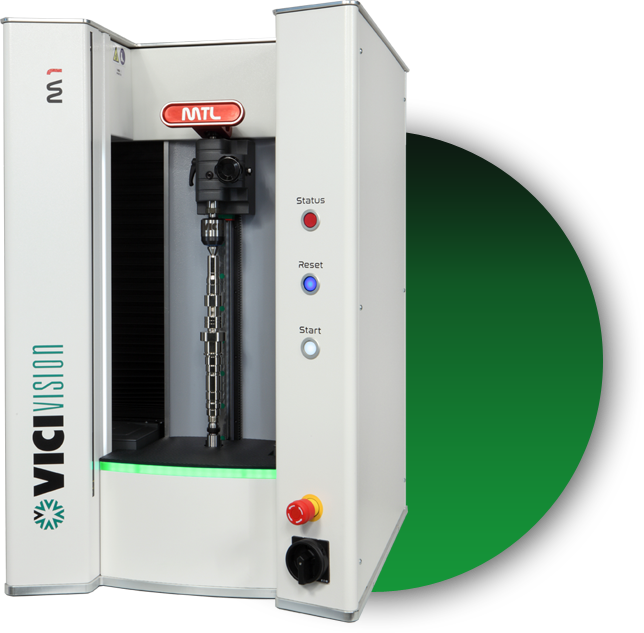

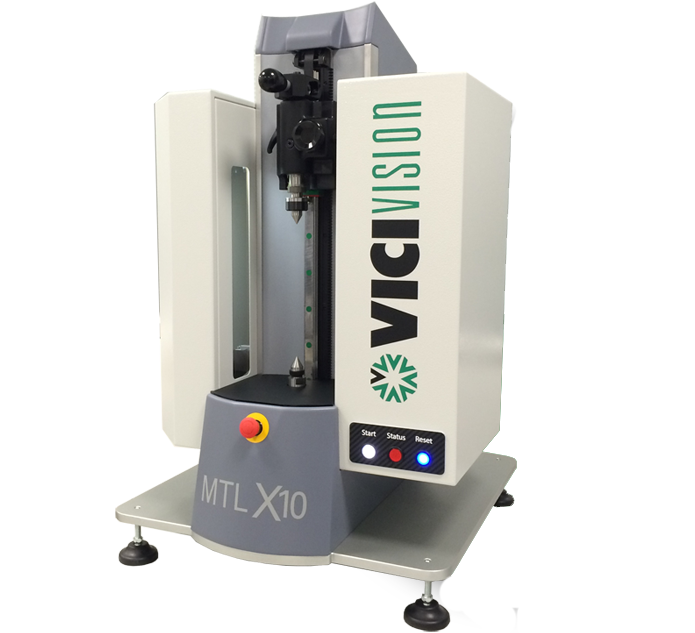

X RANGE: X5/X10

MTL X5 / X10 is the ideal solution for the dimensional control by optical scanning of tuning parts with small dimensions: dental implants, watch components, small screws …

Its high-resolution optics, unique in his class, can detect and measure the smallest geometries.

In a few seconds, MTLX5 / X10 automatically measures by video scanning, the external profile of the part in static and dynamic, to control lengths, diameters, angles, radius, threads, shape defects …

| X5 / X10 | |

| Loading capacity L x Ø (mm) | until 270 x 90 – 3 kgs |

| Measurement capacity L x Ø (mm) | until 270 x 16 |

M RANGE: M1/M2/M3

Even faster, this new series reduces measurement times.

The actual image of the part displayed on the software, combined with the measurement area illuminated by led, makes it possible to better visualize the part to be measured.

The new clamping lever is large enough to suit both right-handed and left-handed operators.

The M-Series measures both small and large trees, and allows you to see every detail, such as the rays and streaks of a room.

The M2 and M3 models can be used to load parts up to 240 mm in diameter.

| M1 / M2 / M3 | |

| Loading capacity L x Ø (mm) | until925 x 240 – 30 kgs |

| Measurement capacity L x Ø (mm) | until 900 x 140 |

TECHNO RANGE : M304 - M1212

From 40 to 180 mm in diameter, from 300 to 1250 mm long, the Techno range allows you to choose the model most suited to your type of production.

The resolution has been improved to visualize every detail of the piece.

In addition, large machines have increased their load capacity by up to 60 kgs.

With this new range, you can now measure all your parts directly in production.

| M304 à M1218 | |

| Loading capacitye L x Ø (mm) | until 1300 x 240 – 60 kgs |

| Measurement capacity L x Ø (mm) | until 1250 x 180 |

NEW : PRIMA RANGE

Vici Vision’s Prima range of machines has been designed to offer you a complete turnkey solution for use directly in the workshop. It is the best answer to current and future production trends!

It is a complete measuring system with the integration of two screens directly on the machine. From 60 to 140 mm diameter and from 300 to 600 mm length, the Prima Vici Vision range adapts to your production.

Each part is measured easily and in a few seconds by the operators, directly on the shop floor. Batch changes are made quickly so that only one system is needed for several machining centres.

| Prima machines | |

| Loading capacity L x Ø (mm) | Until 625 x 240 – 30 kg |

| Measurement capacity L x Ø (mm) | Until 600 x 400 |

X RANGE: X5 / X10 / X360

MTL X5 / X10 is the ideal solution for the dimensional control by optical scanning of tuning parts with small dimensions: dental implants, watch components, small screws …

Its high-resolution optics, unique in his class, can detect and measure the smallest geometries.

In a few seconds, MTLX5 / X10 automatically measures by video scanning, the external profile of the part in static and dynamic, to control lengths, diameters, angles, radius, threads, shape defects …

| X Range | |

| Loading capacity L x Ø (mm) | Until 315 x 120 |

| Measurement capacity L x Ø (mm) | Until 300 x 60 |

TECHNO RANGE : M304 - M1212

From 40 to 180 mm in diameter, from 300 to 2000 mm long, the Techno range allows you to choose the model most suited to your type of production.

The resolution has been improved to visualize every detail of the piece.

In addition, large machines have increased their load capacity by up to 60 kgs.

With this new range, you can now measure all your parts directly in production.

| M304 à M1218 | |

| Loading capacitye L x Ø (mm) | Until 2000 x 240 – 60 kgs |

| Measurement capacity L x Ø (mm) | Until 2000 x 180 |

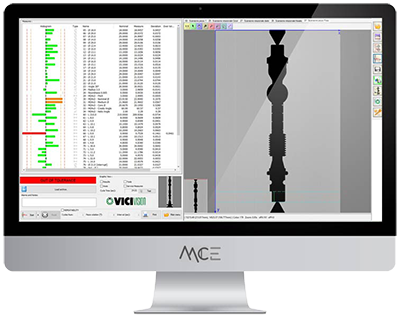

SOFTWARE

- Autoprogramming

- Barcode

- Live picture of your part

- Automatic measurement report

- Offline function

MTL SOFTWARE

Metrology software for Windows: measurement on the picture with automatic scanning … Static or dynamic measurement (rotation of the part).

Standard: Statistical module (control card, Cp, Cpk …), custom report module and ISO thread database …

- Sending corrective values to cnc turning

- Simplified interface

- Import CSV files

- Optimisation of part-program

- Trending visualisation

Tool Loop SOFTWARE

Software allowing interfacing between production machines and Vici Vision machines, corrective values sent automatically to reduce waste.

- Real time production monitoring

- Database of measurements

- Simplified filters

- Customizable report

- Automatic detection of trends

Statistique SOFTWARE

Statistical software for real-time monitoring of the controls and the process -Cp – Cpk

Take some good measurements!

OTHERS

Clamping Accessories: A complete range of accessories to clamp your parts.

Automation: Loading and unloading 100% of your production, integration of a secure cell with robot arm.

Barcode: Switch from one room to another by simply scanning the barcode: Traceability / Statistical Tracking.

Production: Designed for installation directly in the workshop, Vici Vision machines communicate with production machines.

Engineering Office: Development of specific tools, customized solutions.